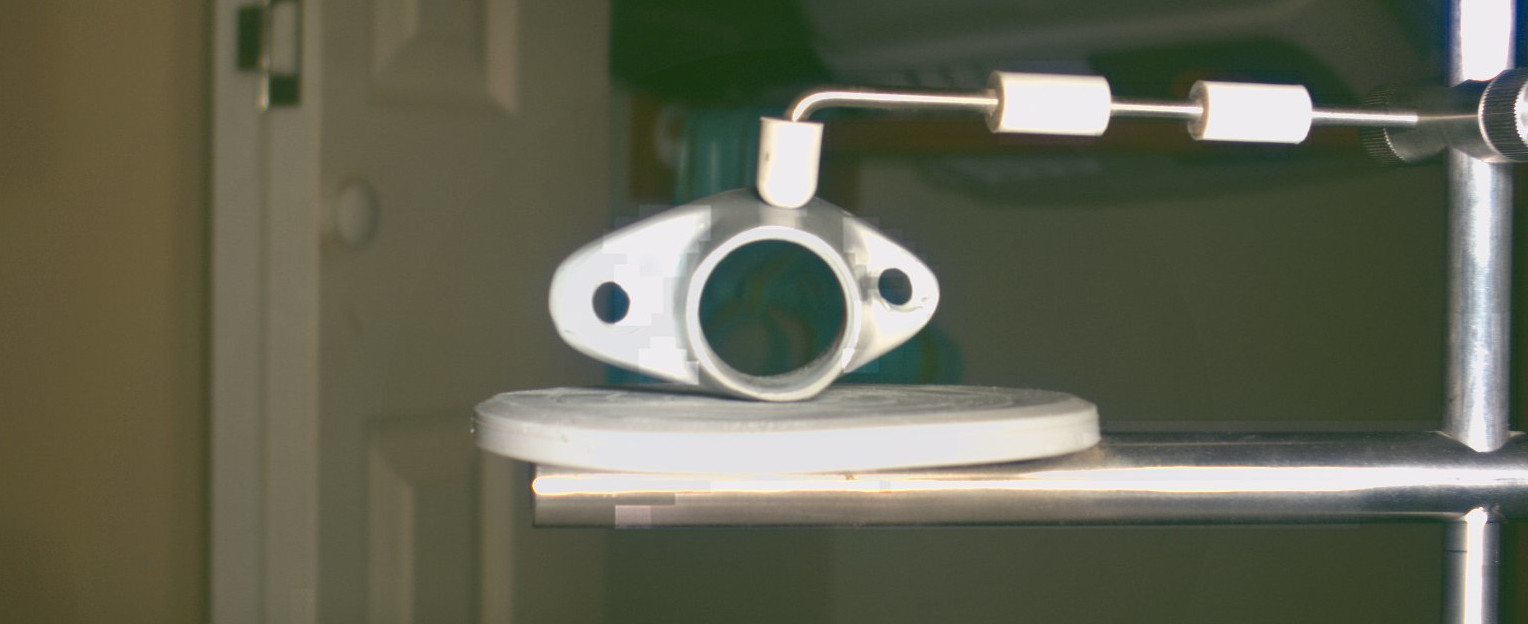

An old friend showed up one day with a pair of old, very sought after mounts for Appleton spotlights for his 1939 Mercury. They weren't his; but he wanted a pair of his own. "Can you make these?" he asked.

The Appleton Mounts

So we did. Using the NextEngine Desktop scanner, we took a high resolution series of points to generate a mesh that approximated the outer shape, and then took analog measurements with a thread gage and snap-bore gauges for the portion that needed a mechanical fit. Then we translated the mesh into a NURBs splines in Autodesk Fusion 360. After that, the design work could begin in earnest; we tweaked and modified the model for machining, and generated a pair of jigs. Then, finally it went to the mill, where we used a complex 3D machining operation to carve out the organic shape as closely as possible to the originals.

Want to know more about the NextEngine 3D scanning system that we use?